Ford Model T 1908- 1927

| Ford Model T | |

|---|---|

1919 Ford Model T Coupe

|

|

| Overview | |

| Manufacturer | Ford Motor Company |

| Production | 1908–1927 |

| Assembly |

United States:

Detroit, Michigan Highland Park, Michigan Dothan, Alabama Los Angeles, California San Francisco, California Minneapolis, Minnesota St. Paul, Minnesota St. Louis, Missouri Omaha, Nebraska Buffalo, New York Cincinnati, Ohio Cleveland, Ohio Columbus, Ohio Dallas, Texas Argentina: Buenos Aires Australia: Geelong, Victoria Brazil: São Bernardo do Campo, São Paulo Canada: Toronto, Ontario Walkerville, Ontario Chile: Santiago Denmark: Copenhagen Germany: Berlin Ireland: Cork Japan: Yokohama Spain: Cádiz United Kingdom: Manchester |

| Designer | Henry Ford, Childe Harold Wills, Joseph A. Galamb and Eugene Farkas |

| Body and chassis | |

| Class | Full-size Ford, economy car |

| Body style |

2-door touring (1909–11)

3-door touring (1912–25) 4-door touring (1926–27) no door roadster (1909–11) 1-door roadster(1912–25) 2-door roadster (1926–27) roadster pickup (1925–27) 2-door coupé (1909–12, 1917–27) 2-door Coupelet (1915–17) Town car (1909–18) C-cab wagon (1912) 2-(Center) door sedan (1915–23) 2-door sedan (1924–27) 4-door sedan (1923–27) Separate chassis were available all years from independent coachbuilders |

| Layout | FR layout |

| Powertrain | |

| Engine | 177 C.I.D. (2.9 L) 20 hp I4 |

| Transmission | 2-speed planetary gear |

| Dimensions | |

| Wheelbase | 100.0 in (2,540 mm) |

| Length | 134 in (3,404 mm) |

| Curb weight | 1,200 pounds (540 kg) |

| Chronology | |

| Predecessor | Ford Model S |

| Successor | Ford Model A |

The Ford Model T (colloquially known as the Tin Lizzie, Leaping Lena, or flivver) is an automobile that was produced by Ford Motor Company from October 1, 1908, to May 26, 1927.

It is generally regarded as the first affordable automobile, the car that opened travel to the common middle-class American; some of this was because of Ford's efficient fabrication, including assembly line production instead of individual hand craftingThe Ford Model T was named the most influential car of the 20th century in the 1999 Car of the Century competition, ahead of the BMC Mini, Citroën DS, and Volkswagen Type 1. Ford's Model T was successful not only because it provided inexpensive transportation on a massive scale, but also because the car signified innovation for the rising middle class and became a powerful symbol of America's age of modernization. With 16.5 million sold it stands eighth on the top ten list of most sold cars of all time as of 2012[update].

Although automobiles had already existed for decades, they were still mostly scarce and expensive at the Model T's introduction in 1908. Positioned as reliable, easily maintained mass market transportation, it was a runaway success. In a matter of days after the release, 15,000 orders were placed. The first production Model T was produced on August 12, 1908 and left the factory on September 27, 1908, at the Ford Piquette Avenue Plant in Detroit, Michigan. On May 26, 1927, Henry Ford watched the 15 millionth Model T Ford roll off the assembly line at his factory in Highland Park, Michigan.

There were several cars produced or prototyped by Henry Ford from the founding of the company in 1903 until the Model T was introduced. Although he started with the Model A, there were not 19 production models (A through T); some were only prototypes. The production model immediately before the Model T was the Model S, an upgraded version of the company's largest success to that point, the Model N. The follow-up was the Ford Model A (rather than any Model U). The company publicity said this was because the new car was such a departure from the old that Henry wanted to start all over again with the letter A.

The Model T was Ford's first automobile mass-produced on moving assembly lines with completely interchangeable parts, marketed to the middle class. Henry Ford said of the vehicle:

I will build a car for the great multitude. It will be large enough for the family, but small enough for the individual to run and care for. It will be constructed of the best materials, by the best men to be hired, after the simplest designs that modern engineering can devise. But it will be so low in price that no man making a good salary will be unable to own one – and enjoy with his family the blessing of hours of pleasure in God's great open spaces.

Although credit for the development of the assembly line belongs to Ransom E. Olds with the first mass-produced automobile, the Oldsmobile Curved Dash, beginning in 1901, the tremendous advancements in the efficiency of the system over the life of the Model T can be credited almost entirely to the vision of Ford and his engineers.

Characteristics

The Model T was designed by Childe Harold Wills, and Hungarian immigrants Joseph A. Galamb and Eugene Farkas. Henry Love, C. J. Smith, Gus Degner and Peter E. Martin were also part of the team. Production of the Model T began in the third quarter of 1908. Collectors today sometimes classify Model Ts by build years and refer to these as "model years", thus labeling the first Model Ts as 1909 models. This is a retroactive classification scheme; the concept of model years as we conceive it today did not exist at the time. The nominal model designation was "Model T", although design revisions did occur during the car's two decades of production.

Engine

| Ford Model T engine | |

|---|---|

|

|

| Overview | |

| Manufacturer | Ford Motor Company |

| Production | 1908–1941 |

| Combustion chamber | |

| Displacement | 177 cu in (2.90 L) |

| Cylinder bore | 3 3⁄4 inches (95.25 mm) |

| Piston stroke | 4 inches (101.6 mm) |

| Cylinder block alloy | cast iron, monobloc design |

| Cylinder head alloy | cast iron, detachable |

| Valvetrain | side valve (flathead) |

| Combustion | |

| Fuel system | gravity feed, carburetted |

| Fuel type | flex-fuel, primarily gasoline |

| Cooling system | water, thermosyphon |

| Output | |

| Power output | 20 hp (15 kW) |

Side view of Ford Model T engine.

The Ford Model T used a 177 cu in (2.

90 L) inline 4-cylinder engine It was primarily a petrol engine, but it had flex-fuel ability (called multifuel at the time) and could also burn kerosene or alcohol It produced 20 hp (15 kW) for a top speed of 45 mph (72 km/h) It was built in-unit with the Model T's novel transmission (a planetary design), sharing the same lubricating oilThe T engine was known for its simplicity, reliability, and economy. The engine remained in production for many years, and millions of units were produced. The engine design's lifespan exceeded that of the Model T vehicle itself, with industrial, marine, and military applications extending its production run. The T engine is on the Ward's 10 Best Engines of the 20th Century list.

Fuel choices and fuel economy

The T engine was primarily a petrol engine, but it had multifuel ability and could also burn kerosene or ethanol.[citation needed] According to Ford Motor Company, the Model T had fuel economy on the order of 13–21 mpg‑US (16–25 mpg‑imp; 18–11 L/100 km).

Carburetor and fuel system

Cutaway view of the fuel system for the Ford Model T engine, showing the gravity-feed fuel supply, carburetor cutaway, and intake stream.

The T engine had one carburetor, a side-draft, single-venturi unit. Its choke and throttle valves were controlled manually; the latter was with a hand lever rather than a foot pedal. The carburetor had no accelerator pump. Various vendors supplied Ford with carburetors for the T engine, including Holley, Zenith, and Kingston.

During most of the T's production run, its 10 US gal (38 l; 8 imp gal) fuel tank was mounted to the frame beneath the front seat. Because Ford relied on gravity to feed fuel to the carburetor rather than a fuel pump, a Model T could not climb a steep hill when the fuel level was low. The immediate solution was to climb steep hills in reverse. In 1926, the fuel tank was moved forward and upward, under the cowl, on most models, which improved the gravity feed.

Internal design

Cutaway internal view of Ford Model T engine.

The T engine was an inline-four, with all four cylinders cast into one engine block. Such monobloc design was an uncommon practice when T production started in 1908. It lent itself to mass production, showing the Ford company's prescient focus on design for manufacturability. The head, however, was detachable, which not only aided Ford in manufacturing but also made valve jobs (cleaning, grinding, or replacement of the poppet valves) easier. The block and head were both of cast iron.

The engine's bore was 3 3⁄4 inches (95.25 mm) and its stroke was 4 inches (101.6 mm) even, for a total displacement of 177 cu in (2,900 cc). The compression ratio was low by modern standards, but typical for the era, making the engine forgiving of poor fuel quality and minimizing cranking effort at starting.

The valvetrain was a side valve (flathead) design.

The crankshaft had 3 main bearings.

Cooling system

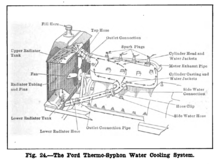

Overview of the thermosyphon cooling system of the Ford Model T engine.

The T engine's cooling system reflected the T's simplicity design theme. The first few hundred Model Ts had a water pump, but it was eliminated early in production. Instead, Ford opted for a cheaper and more reliable thermosyphon system. Thermosyphon was a common engine-cooling method of the era. Hot water, being less dense, would rise to the top of the engine and up into the top of the radiator, descending to the bottom as it cooled, and back into the engine. (This was the direction of water flow in most cars which did have water pumps, until the introduction of crossflow radiator designs.) The thermosiphon system was susceptible to overheating if worked heavily, but served well for most Model T usage.

Many types of water pumps were available as aftermarket accessories.

Ignition system

Overview of the ignition system of the Ford Model T engine.

The Model T engine's ignition system used a flywheel-mounted magneto to produce the current necessary to produce a spark to initiate combustion. This current was distributed by the timer (analogous to a distributor in a modern vehicle) to one of the four trembler coils, one for each cylinder. The coil stepped up the voltage and discharged it to the spark plug in the cylinder. Ignition timing was adjusted manually by using the spark advance lever mounted on the steering column, which rotated the timer, advancing or retarding the ignition timing. A battery could be used for starting current: at hand-cranking speed, the magneto did not always produce sufficient current. A starting battery was not standard equipment until sometime in 1926, though all T's had a "BAT" position ("battery") on the coil box switch. A certain amount of skill and experience was required to find the optimal spark timing for any speed and load.

The magneto was the first Model T component to be assembled on an assembly line, and the method was copied to many other Model T production segments. The ignition system of the Fordson tractor was similar to the Model T's.

Starting, lights, and electrical system beyond ignition

When electric headlights were introduced in 1915, the magneto was upgraded to supply enough power for the lights and horn. In the early years of Model T production, all Ts were started with a hand crank. Most cars sold after 1919 were equipped with an electric starter, which was engaged by a small round foot-operated button switch on the floor. In keeping with the goal of ultimate reliability and simplicity, the trembler coil and magneto ignition system was retained even after the car became equipped with a generator and larger battery for electric starting and lighting.

Operation

Overhead views of Ford Model T engine, with the head removed in one view.

Operating the T engine was not difficult after some experience, although the learning curve was longer than today's. The various manual control tasks (such as manual choke and spark advance) and the method of use (such as hand throttle) were typical for automobiles of the era, although they might seem more like farm tractor operation to most automobile drivers of today.

Before starting a Model T with the hand crank, the spark had to be manually retarded or the engine might "kick back". The crank handle was cupped in the palm, with the thumb tucked under the handle (not clasped over top of it), so that if the engine did kick back, the rapid reverse motion of the crank would throw the hand away from the handle, rather than violently twisting the wrist or breaking the thumb. Most Model T Fords had the choke operated by a wire emerging from the bottom of the radiator where it could be operated with the left hand. This was used to prime the engine while cranking the engine slowly; then the engine was started with a rapid pull of the crank handle. In good tune, an already-primed T engine only has to be cranked half a turn for it to successfully start.

The T's planetary transmission is famous for its differences from what later became the norm for car transmission operation. The 3 foot pedals are not used in the way later cars use their pedals. Operation is not difficult but requires "unlearning" habits used with later vehicles.

Design changes over the years

The following major changes were made (listed by year):

- 1909 — First model year - Water pump was discontinued; subsequent Model T engines used thermosyphoning to circulate the coolant.

- 1911 — Valve covers were added

- 1917 — Higher head with larger water jacket

- 1919 — Engine starter introduced as an option

- 1920 — Lighter-weight rods and pistons

- 1922 — The cylinder casting was changed so a single valve cover could be used

- 1926 — An extra boss was added at the rear for two additional bolts stiffening the transmission,

- 1927 — The carburetor throttle rod was re-routed over the engine

Production run

The T engine was produced continuously from September 27, 1908, through August 4, 1941, exactly 12,000 days. This makes it one of the longest engines in series production, especially considering that the specifications remained mostly unchanged for this entire duration. Its production run for the U.S. consumer market for passenger cars and pickups was shorter, being the 19 years' production run of the Model T itself for that market (1908 to 1927). But the engine continued to be produced and sold to various consumer, industrial, military, and marine markets throughout the world until 1941.

Transmission and drive train

The Model T was a rear-wheel drive vehicle. Its transmission was a planetary gear type billed as "three speed". In today's terms it would be considered a two-speed, because one of the three speeds was reverse.

The Model T's transmission was controlled with three foot pedals and a lever that was mounted to the road side of the driver's seat. The throttle was controlled with a lever on the steering wheel. The left pedal was used to engage the gear. With the floor lever in either the mid position or fully forward and the pedal pressed and held forward the car entered low gear. When held in an intermediate position the car was in neutral. If the left pedal was released, the Model T entered high gear, but only when the lever was fully forward – in any other position the pedal would only move up as far as the central neutral position. This allowed the car to be held in neutral while the driver cranked the engine by hand. The car could thus cruise without the driver having to press any of the pedals. There was no separate clutch pedal.

When the car was in neutral, the middle pedal was used to engage reverse gear, and the right pedal operated the transmission brake – there were no separate brakes on the wheels. The floor lever also controlled the parking brake, which was activated by pulling the lever all the way back. This doubled as an emergency brake.

Although it was uncommon, the drive bands could fall out of adjustment, allowing the car to creep, particularly when cold, adding another hazard to attempting to start the car: a person cranking the engine could be forced backward while still holding the crank as the car crept forward, although it was nominally in neutral. As the car utilized a wet clutch, this condition could also occur in cold weather, when the thickened oil prevents the clutch discs from slipping freely. Power reached the differential through a single universal joint attached to a torque tube which drove the rear axle; some models (typically trucks, but available for cars as well) could be equipped with an optional two-speed Ruckstell rear axle shifted by a floor-mounted lever which provided an underdrive gear for easier hill climbing. All gears were vanadium steel running in an oil bath.

Transmission bands and linings

Two main types of band lining material were used:

- Cotton – Cotton woven linings were the original type fitted and specified by Ford. Generally, the cotton lining is "kinder" to the drum surface, with damage to the drum caused only by the retaining rivets scoring the drum surface. Although this in itself did not pose a problem, a dragging band resulting from improper adjustment caused overheating transmission and engine, diminished power, and – in the case of cotton linings – rapid destruction of the band lining.

- Wood – Wooden linings were originally offered as a "longer life" accessory part during the life of the Model T. They were a single piece of steam bent cottonwood[citation needed] fitted to the normal Model T transmission band. These bands give a very different feel to the pedals, with much more of a "bite" feel. The sensation is of a definite "grip" of the drum and seemed to noticeably increase the feel, in particular of the brake drum.

Suspension and wheels

Model T suspension employed a transversely mounted semi-elliptical spring for each of the front and rear beam axles which allowed a great deal of wheel movement to cope with the dirt roads of the time.

The front axle was drop forged as a single piece of vanadium steel. Ford twisted many axles through eight full rotations (2880 degrees) and sent them to dealers to be put on display to demonstrate its superiority. The Model T did not have a modern service brake. The right foot pedal applied a band around a drum in the transmission, thus stopping the rear wheels from turning. The previously mentioned parking brake lever operated band brakes acting on the inside of the rear brake drums, which were an integral part of the rear wheel hubs. Optional brakes that acted on the outside of the brake drums were available from aftermarket suppliers.

Wheels were wooden artillery wheels, with steel welded-spoke wheels available in 1926 and 1927.

Tires were pneumatic clincher type, 30 in (76 cm) in diameter, 3.5 in (8.9 cm) wide in the rear, 3 in (7.5 cm) wide in the front. Clinchers needed much higher pressure than today's tires, typically 60 psi (410 kPa), to prevent them from leaving the rim at speed. Horseshoe nails on the roads, together with the high pressure, made flat tires a common problem.

Balloon tires became available in 1925. They were 21 in × 4.5 in (53 cm × 11 cm) all around. Balloon tires were closer in design to today's tires, with steel wires reinforcing the tire bead, making lower pressure possible – typically 35 psi (240 kPa) – giving a softer ride. The old nomenclature for tire size changed from measuring the outer diameter to measuring the rim diameter so 21 in (530 mm) (rim diameter) × 4.5 in (110 mm) (tire width) wheels has about the same outer diameter as 30 in (76 cm) clincher tires. All tires in this time period used an inner tube to hold the pressurized air; tubeless tires were not generally in use until much later.

Wheelbase was 100 inches (254 cm) and standard tread width was 56 in (142 cm); 60 in (152 cm) tread could be obtained on special order, "for Southern roads", identical to the pre-Civil War track gauge for many railroads in the former Confederacy.

Colors

By 1918, half of all the cars in the US were Model Ts. However, it was a monolithic bloc; Ford wrote in his autobiography that in 1909 he told his management team that in the future “Any customer can have a car painted any color that he wants so long as it is black”.

However, in the first years of production from 1908 to 1913, the Model T was not available in black but rather only gray, green, blue, and red. Green was available for the touring cars, town cars, coupes, and Landaulets. Gray was only available for the town cars, and red only for the touring cars. By 1912, all cars were being painted midnight blue with black fenders. It was only in 1914 that the "any color so long as it is black" policy was finally implemented. It is often stated that Ford suggested the use of black from 1914 to 1926 due to the cheap cost and durability of black paint. During the lifetime production of the Model T, over 30 types of black paint were used on various parts of the car. These were formulated to satisfy the different means of applying the paint to the various parts, and had distinct drying times, depending on the part, paint, and method of drying.

Body

Although Ford classified the Model T with a single letter designation throughout its entire life and made no distinction by model years, there were enough significant changes to the body over the production life that the car may be classified into several style categories. Among the most immediately visible and identifiable changes were in the hood and cowl areas, although many other modifications were made to the vehicle.

- 1909–1914 – Characterized by a nearly straight, five-sided hood, with a flat top containing a center hinge and two side sloping sections containing the folding hinges. The firewall was flat from the windshield down with no distinct cowl.

- 1915–1916 – The hood design was nearly the same five sided design with the only obvious change being the addition of louvers to the vertical sides. There was a significant change to the cowl area with the windshield relocated significantly behind the firewall and joined with a compound contoured cowl panel.

- 1917–1923 – The hood design was changed to a tapered design with a curved top. the folding hinges were now located at the joint between the flat sides and the curved top. This is sometime referred to as the low hood to distinguish if from the later hoods. The back edge of the hood now met the front edge of the cowl panel so that no part of the flat firewall was visible outside of the hood. This design was used the longest and during the highest production years accounting for about half of the total number of Model T's built.

- 1923–1925 – This change was made during the 1923 calendar year so models built earlier in the year have the older design while later vehicles have the newer design. The taper of the hood was increased and the rear section at the firewall is about an inch taller and several inches wider than the previous design. While this is a relatively minor change, the parts between the third and fourth generation are not interchangeable.

- 1926–1927 – This design change made the greatest difference in the appearance of the car. The hood was again enlarged with the cowl panel no longer a compound curve and blended much more with the line of the hood. The distance between the firewall and the windshield was also increased significantly. This style is sometimes referred to as the high hood.

The styling on the last "generation" was a preview for the following Model A but the two models are visually quite different as the body on the A was much wider and had curved doors as opposed to the flat doors on the T.

Diverse applications

When the Model T was designed and introduced, the infrastructure of the world was quite different from today's. Pavement was a rarity except for sidewalks and a few big-city streets. (The sense of the term "pavement" as equivalent with "sidewalk" comes from that era, when streets and roads were generally dirt and sidewalks were a paved way to walk along them.) Agriculture was the occupation of many people. Power tools were scarce outside factories, as were power sources for them; electrification, like pavement, was found usually only in larger towns. Rural electrification and motorized mechanization were embryonic in some regions and nonexistent in most. Henry Ford oversaw the requirements and design of the Model T based on contemporary realities. Consequently, the Model T was (intentionally) almost as much a tractor and portable engine as it was an automobile. It has always been well regarded for its all-terrain abilities and ruggedness. It could travel a rocky, muddy farm lane, cross a shallow stream, climb a steep hill, and be parked on the other side to have one of its wheels removed and a pulley fastened to the hub for a flat belt to drive a bucksaw, thresher, silo blower, conveyor for filling corn cribs or haylofts, baler, water pump, electrical generator, and many other applications. One unique application of the Model T was shown in the October 1922 issue of Fordson Farmer magazine. It showed a minister who had transformed his Model T into a mobile church, complete with small organ.

During this era, entire automobiles (including thousands of Model Ts) were even hacked apart by their owners and reconfigured into custom machinery permanently dedicated to a purpose, such as homemade tractors and ice saws,. Dozens of aftermarket companies sold prefab kits to facilitate the T's conversion from car to tractor. The Model T had been around for a decade before the Fordson tractor became available (1917–18), and many Ts had been converted for field use. (For example, Harry Ferguson, later famous for his hitches and tractors, worked on Eros Model T tractor conversions before he worked with Fordsons and others.) During the next decade, Model T tractor conversion kits were harder to sell, as the Fordson and then the Farmall (1924), as well as other light and affordable tractors, served the farm market. But during the Depression (1930s), Model T tractor conversion kits had a resurgence, because by then used Model Ts and junkyard parts for them were plentiful and cheap.

Like many popular car engines of the era, the Model T engine was also used on home-built aircraft (such as the Pietenpol Sky Scout) and motorboats.

An armored car variant (called the FT-B) was developed in Poland in 1920.

Many Model Ts were converted into vehicles which could travel across heavy snows with kits on the rear wheels (sometimes with an extra pair of rear-mounted wheels and two sets of continuous track to mount on the now-tandemed rear wheels, essentially making it a half-track) and skis replacing the front wheels. They were popular for rural mail delivery for a time. The common name for these conversions of cars and small trucks was "snowflyers". These vehicles were extremely popular in the northern reaches of Canada where factories were set up to produce them.

A number of companies built Model T–based railcars. In The Great Railway Bazaar, Paul Theroux mentions a rail journey in India on such a railcar. The New Zealand Railways Department's RM class included a few.

Production

Mass production

The knowledge and skills needed by a factory worker were reduced to 84 areas. When introduced, the T used the building methods typical at the time, assembly by hand, and production was small. The Ford Piquette Avenue Plant could not keep up with demand for the Model T, and only 11 cars were built there during the first full month of production. More and more machines were used to reduce the complexity within the 84 defined areas. In 1910, after assembling nearly 12,000 Model Ts, Henry Ford moved the company to the new Highland Park complex.

As a result, Ford's cars came off the line in three-minute intervals, much faster than previous methods, reducing production time by a factor of eight (requiring 12.5 hours before, 93 minutes afterwards), while using less manpower. By 1914, the assembly process for the Model T had been so streamlined it took only 93 minutes to assemble a car. That year Ford produced more cars than all other automakers combined. The Model T was a great commercial success, and by the time Henry made his 10 millionth car, 50 percent of all cars in the world were Fords. It was so successful that Ford did not purchase any advertising between 1917 and 1923, instead it became so famous that people now considered it a norm; more than 15 million Model Ts were manufactured, reaching a rate of 9,000 to 10,000 cars a day in 1925, or 2 million annually, more than any other model of its day, at a price of just $260. Model T production was finally surpassed by the Volkswagen Beetle on February 17, 1972.

Henry Ford's ideological approach to Model T design was one of getting it right and then keeping it the same; he believed the Model T was all the car a person would, or could, ever need. As other companies offered comfort and styling advantages, at competitive prices, the Model T lost market share. Design changes were not as few as the public perceived, but the idea of an unchanging model was kept intact. Eventually, on May 26, 1927, Ford Motor Company ceased US production and began the changeovers required to produce the Model A. Some of the other Model T factories in the world continued a short while.

Model T engines continued to be produced until August 4, 1941. Almost 170,000 were built after car production stopped, as replacement engines were required to service already produced vehicles. Racers and enthusiasts, forerunners of modern hot rodders, used the Model T's block to build popular and cheap racing engines, including Cragar, Navarro, and famously the Frontenacs ("Fronty Fords") of the Chevrolet brothers, among many others.

The Model T employed some advanced technology, for example, its use of vanadium steel alloy. Its durability was phenomenal, and some Model Ts and their parts are in running order over a century later. Although Henry Ford resisted some kinds of change, he always championed the advancement of materials engineering, and often mechanical engineering and industrial engineering.

In 2002, Ford built a final batch of six Model Ts as part of their 2003 centenary celebrations. These cars were assembled from remaining new components and other parts produced from the original drawings. The last of the six was used for publicity purposes in the UK.

Although Ford no longer manufactures parts for the Model T, many parts are still manufactured through private companies as replicas to service the thousands of Model Ts still in operation today.

On May 26, 1927 Henry Ford and his son Edsel, drove the 15 millionth Model T out of the factory. This marked the famous automobile's official last day of production at the main factory.

Price and production

The assembly line system allowed Ford to sell his cars at a price lower than his competitors due to the efficiency of the system. As he continued to fine-tune the system, he was able to keep reducing his costs. As his volume increased, he was able to also lower the prices due to fixed costs being spread over a larger number of vehicles. Other factors affected the price such as material costs and design changes.

The figures below are US production numbers compiled by R.E. Houston, Ford Production Department, August 3, 1927. The figures between 1909 and 1920 are for Ford's fiscal year. From 1909 to 1913, the fiscal year was from October 1 to September 30 the following calendar year with the year number being the year it ended in. For the 1914 fiscal year, the year was October 1, 1913 through July 31, 1914. Starting in August 1914, and through the end of the Model T era, the fiscal year was August 1 through July 31. Beginning with January 1920 the figures are for the calendar year.

| Year | Production | Price for Runabout |

Notes |

|---|---|---|---|

| 1909 | 10,666 | $825 | ($22,000 in 2016) Touring car was $850 |

| 1910 | 19,050 | $900 | |

| 1911 | 34,858 | $680 | |

| 1912 | 68,773 | $590 | |

| 1913 | 170,211 | $525 | |

| 1914 | 202,667 | $440 | Fiscal year was only 10 months long due to change in end date from Sep 30 to July 31 |

| 1915 | 308,162 | $390 | |

| 1916 | 501,462 | $345 | |

| 1917 | 735,020 | $500 | |

| 1918 | 664,076 | $500 | |

| 1919 | 498,342 | $500 | |

| 1920 | 941,042 | $395 | Production for fiscal year 1920, (August 1, 1919 through July 31, 1920) Price was $550 in March but dropped by Sept |

| 1920 | 463,451 | $395 | Production for balance of calendar year, August 1 through Dec 31 Total '1920' production (17 months) = 1,404,493 |

| 1921 | 971,610 | $325 | Price was $370 in June but dropped by Sept. |

| 1922 | 1,301,067 | $319 | |

| 1923 | 2,011,125 | $364 | |

| 1924 | 1,922,048 | $265 | |

| 1925 | 1,911,705 | $260 | ($3,550 in 2016) Touring car was $290 |

| 1926 | 1,554,465 | $360 | |

| 1927 | 399,725 | $360 | Production ended before mid-year to allow retooling for the Model A |

| 14,689,525 | Overall total |

Recycling

Henry Ford used wood scraps from the production of Model Ts to make charcoal. Originally named Ford Charcoal, the name was changed to Kingsford Charcoal after Ford's brother-in-law E. G. Kingsford brokered the selection of the new charcoal plant site. Lumber for production of the Model T came from the same location, built in 1920 called the Ford Iron Mountain Plant, which incorporated a sawmill where lumber from Ford purchased land in the Upper Peninsula of Michigan was sent to the River Rouge Plant; scrap wood was then returned for charcoal production.[citation needed]

First global car

The Ford Model T was the first automobile built by various countries simultaneously since they were being produced in Walkerville, Canada and in Trafford Park, Greater Manchester, England starting in 1911 and were later assembled in Germany, Argentina, France, Spain, Denmark, Norway, Belgium, Brazil, Mexico, and Japan, as well as several locations throughout the US. Ford made use of the knock-down kit concept almost from the beginning of the company as freight and production costs from Detroit had Ford assembling vehicles in major metropolitan centers of the US.

The Aeroford was an English automobile manufactured in Bayswater, London, from 1920 to 1925. It was a Model T with distinct hood and grille to make it appear to be a totally different design, what later would have been called badge engineering. The Aeroford sold from £288 in 1920, dropping to £168-214 by 1925. It was available as a two-seater, four-seater, or coupé.[page needed]

Advertising and marketing

Ford created a massive publicity machine in Detroit to ensure every newspaper carried stories and advertisements about the new product. Ford's network of local dealers made the car ubiquitous in virtually every city in North America. A large part of the success of Ford's Model T stems from the innovative strategy which introduced a large network of sales hubs making it easy to purchase the car. As independent dealers, the franchises grew rich and publicized not just the Ford but the very concept of automobiling; local motor clubs sprang up to help new drivers and to explore the countryside. Ford was always eager to sell to farmers, who looked on the vehicle as a commercial device to help their business. Sales skyrocketed – several years posted around 100 percent gains on the previous year.

Car clubs

Cars built before 1919 are classed as veteran cars and later models as vintage cars. Today, four main clubs exist to support the preservation and restoration of these cars: the Model T Ford Club International, the Model T Ford Club of America and the combined clubs of Australia. With many chapters of clubs around the world, the Model T Ford Club of Victoria has a membership with a considerable number of uniquely Australian cars. (Australia produced its own car bodies, and therefore many differences occurred between the Australian bodied tourers and the US/Canadian cars.) In the UK, the Model T Ford Register of Great Britain celebrated its 50th anniversary in 2010. Many steel Model T parts are still manufactured today, and even fiberglass replicas of their distinctive bodies are produced, which are popular for T-bucket style hot rods (as immortalized in the Jan and Dean surf music song "Bucket T", which was later recorded by The Who).[citation needed] In 1949, more than twenty years after the end of production, 200,000 Model Ts were registered in the United States. In 2008, it was estimated that about 50,000 to 60,000 Ford Model Ts remain roadworthy.

In popular media

- The Ford Model T was coming choice of car for celebrity duo Stan Laurel and Oliver Hardy. It was used in most of their short and feature films.

- The phrase to "go the way of the Tin Lizzie" is a colloquialism referring to the decline and elimination of a popular product, habit, belief or behavior as a now outdated historical relic which has been replaced by something new.

- In Aldous Huxley's Brave New World, Henry Ford is regarded as a messianic figure, Christian crosses have been truncated to T's, and vehicles are called "flivvers" (utilizing a slang reference to the Model T). Moreover, the calendar is converted to an A.F. ("After Ford") system, wherein the first calendar year (A.F. 1) leads from the introduction of the Model T (A.D. 1908).

- The Irish rock group Thin Lizzy derived their name from the Tin Lizzie.[citation needed]

Gallery

Model T chronology

-

1908 Runabout - Note flat firewall

-

1910 Runabout

-

1911 Touring

-

1913 Runabout

-

1914 Touring

-

1915 Runabout - Note curved cowl panel

-

1916 Touring

-

1917 Runabout - Note new curved hood matches cowl panel

-

1919 Runabout

-

1920 Touring

-

1921 Touring

-

1922 flatbed truck

-

1923 Ford Model T Depot Hack

-

1923 Runabout (early '23 model)

-

1924 Touring - Note higher hood and slightly shorter cowl panel - late '23 models were similar

-

1925 Touring

-

1926 Ford T Roadster in Coimbatore, India]]

-

1926 Runabout - Note higher hood and longer cowl panel

-

1926 Touring

-

1926 Ford Model T Tudor

-

1927 Runabout

-

1928 Ford Model A Tudor Sedan - Shown for comparison, note wider body and curved doors