|

|

|

|

| Industry | Automotive |

|---|---|

| Fate | Acquired |

| Founded | 1922 |

| Defunct | January 14, 2010 |

| Headquarters | Kalamazoo, Michigan, U.S. |

|

Key people

|

Morris Markin (founder) |

| Products | automotive stampings and components (previous: Commercial Vehicles, 1922-82 - Consumer Vehicles, 1959-82) |

Checker Motors Corporation was a Kalamazoo, Michigan-based vehicle manufacturer and tier-one subcontractor that manufactured taxicabs used by Checker Taxi.

Checker Motors Corporation was established by Morris Markin in 1922 through a merger of Commonwealth Motors and Markin Automobile Body

Checker made the iconic American taxi cab, valued by taxicab companies for its durability in heavy use. Special features included wide rear doors, large rear seats and trunks. The company had trouble competing with fleet discounts offered by the larger manufacturers, as well as economies of scale in procuring components. The final models were produced in 1982.

On January 16, 2009, the company filed for Chapter 11 protection in U.S. Bankruptcy Court.

History

Morris Markin (a clothier from Chicago, Illinois) became the owner of Markin Automobile Body, an auto-body manufacturer based in Joliet, Illinois, following a default by the owner on a $15,000 personal loan. The facility made bodies for Commonwealth Motors, which marketed the vehicles to cab companies under the trade name Mogul.

Commonwealth Motors was on the verge of bankruptcy, but had an order from Checker Taxi (a privately owned cab company in Chicago that had no affiliation with Markin at the time). Markin merged Commonwealth Motors with Markin Automobile Body to honor the contractual commitment. In 1930, Checkers came in either black, maroon, yellow or canary.

Markin would slowly acquire Checker Taxi of Chicago over the course of the 1920s. In 1929, he purchased the Yellow Cab Company from John D. Hertz.

1920s Models

| Model(year) | Engine | HP | wheelbase | Passengers |

|---|---|---|---|---|

| Model C-44 (1922) | 4-cylinder | 40 | N/A | 5-7 |

| Model H-2 (1923) | 4-cylinder | 22.5 | 127 in (3,226 mm) | 5 |

| Model E (1924) | 4-cylinder | 22.5 | 117 in (2,972 mm) | 5 |

| Model E (1925-1926) | 4-cylinder | 22.5 | 117 in (2,972 mm) | 5 |

| Model F (1926-1927) | 4-cylinder | 22.5 | 117 in (2,972 mm) | 5 |

| Model G-4 (1927-1928) | 4-cylinder | 22.5 | 117 in (2,972 mm) | 5 |

| Model G-6 (1927-1928) | 6-cylinder | 27.30 | 124.75 in (3,169 mm) | 5 |

| Model K-6 (1929) | 6-cylinder | 27.30 | 127 in (3,226 mm) | 6 |

There were major changes at Checker in 1928 with a truly new model, the Model K. An advanced, modern design for its day, it was now a purpose built taxi with luxurious town car styling cues. The body was integrated in its design bumper to bumper; no longer did it possess the Commonwealth Mogul front clip mated to a taxicab body first introduced in 1918.

The Model K was Checker’s first ground up design, introduced 6 years after the founding of Checker. Consistent with previous Checkers, the Model K utilized a 127-inch wheelbase and the Buda six-cylinder was now the only engine available. Within the first month of introduction, there were over 4,800 orders. By January 1929, 950 units had been produced and sold. At the end of January 1929, over 8,000 Checkers were chasing fares in New York City, a city with a total population of 21,000 cabs. This made Checker one of the two dominant taxicab builders in the US, the other being Yellow Cab Manufacturing. Together, the two taxicab manufacturers pushed the other taxicab producers, Premier, Pennant and HCS, out of the market. These two taxicab giants would slug it out through the next decade.

1931 was a profitable year for Checker, but that would soon change in 1932 as the depression finally caught up with the company and after several profitable years, sales collapsed and Checker started to bleed money, generating losses month after month. So bad was the economy that Checker shut down for several weeks at the tail end of 1932. Despite the losses of 1932 and using minimal funds, Checker was able to introduce a new taxicab for 1933, the Model T. The new taxicab utilized the new Lycoming GU or GUC 8-cylinder engine produced by Lycoming of Lewistown, Pennsylvania, an independent engine manufacturer owned by E L Cord, whose growing automotive empire included such iconic brands as Auburn, Cord and Duesenberg (A-C-D).

In 1933 Checker would also produce a brand-engineered version of the Model T, the Auburn Safe-T-Cab for A-C-D, which was sold in limited numbers to the Safe-T-Cab Company in Cleveland. Checker was now partnering significantly with A-C-D.

1933 found many auto manufacturers in the midst of significant financial issues. Checker now needed to recapitalize. Unfortunately for Checker CEO Morris Markin, via a series of capital transactions, essentially a hostile corporate takeover ensued. The corporate board was reduced in size by a group of investors led by millionaire Pierre S. du Pont. The smaller board, which included du Pont voted Markin out of Checker.

Morris Markin had a few tricks up his sleeve. He still maintained some degree of ownership and held options to acquire a majority share of the company.Ten days later Markin secured the required funds via E L Cord to take back control of company Checker. With funds secured, new ownership in place and an alliance with A-C-D: E. L. Cord now owned Checker and the companies were vertically integrated into A-C-D, this allowed Checker to autonomously and still utilize Herb Snow's engineering talent.

Three short years later Cord would run into some trouble. In 1936, Cord came under investigation by the Securities and Exchange Commission for his dealings in Checker Cab stock. In order to avoid prosecution in 1937 Cord sold the Cord Corporation to the Aviation Corporation. Morris Markin was able to secure complete control of Checker. Auburn, Cord and Duesenberg faded away but Checker continued on producing taxicabs.

In 1934, Checker began development of a new taxicab, the Model Y. It was the third offering in the evolution of the 1928 Model K and quite striking in appearance, with many style cues reminiscent of its new corporate cousin, the Auburn, albeit an industrial version.

The Model Y also served as a platform for many new Checker concepts to be utilized for the next 50 years. The long wheelbase version could be purchased in 6 and 8 door variations and also offered an integrated body trunk, a first in the automotive industry. This configuration yielded the first mass-produced car with a three box design, years ahead of 47 Studebaker and 49 Ford post-war offerings.

Other features included a multi-position adjustable driver seat and glass windows in the roof that passengers would love when sightseeing in major cities. Looks alone were not the only similarities to Auburn; the Model Y utilized the Lycoming 148 hp inline GFD 8, the same engine used in the Auburn 850, although later in 1936 there was the option of a 6-cylinder Continental engine. This taxicab would be produced until 1939.

The Model A was put on sale in 1940. When the Checker Model A was introduced it had more interior room than any previous model produced. It was also the first Checker to migrate away from the limousine concept with its driver dividers, focusing on the taxi commodity business: the Model A brochure, placed significant emphasis that taxi operators should consider themselves the seller of a commodity and should think of new ways to attract customers.

The Model A, Checker incorporated new features to enhance the taxi passenger riding experience, including the new landaulet top, where at a touch of a finger, the driver could lower the back section of the roof so that passengers could ride in an open-air mode. If shade was required, a cloth awning could be inserted to reduce the effects of the sun, yet still maintain the open-air feel. Passengers in the jump seats were not left out of the experience, because above their heads was a ventilated glass roof that passengers could open to increase the flow of fresh air, yet still sight=see through the glass roof. Both the glass roof and the landaulet roof were Checker exclusive features, patented in 1936 and 1939 respectively.

The taxi driver also rode with the comfort of Checker exclusive features. Checker claimed that the seat could be adjusted in no less than 15 positions, because the company had always maintained that a comfortable seat would allow the driver to drive longer shifts and yield greater profits for taxicab operators. This Checker exclusive had been patented in 1931. Above the driver's head was a vent in the roof to allow fresh air to flow into the driver compartment. The driver compartment was now protected during all four seasons and for the first time was heated. Gone were the days of drivers being exposed to the weather. The manual transmission shift was moved to the steering column, again in an effort to improve the overall driving experience.

From the rear back, the Model A has the very tasteful streamline styling that was very popular at the time; that said, the Model A front end has always garnered strong opinions from automobile fans. Early artist renditions of the Model A depict an integrated streamline design from fore to aft, but the production car sports a unique, even gothic front clip. It's unclear why the major change in the front end styling was made to the production vehicle, but it has been said that the “sugar scoop” fenders, inherited in part from the preceding Model Y were purpose built to provide safety from tire damage in minor city traffic accidents. At the time, other taxis with streamlined fenders ran the risk of having a tyre pierced in a minor accident, whereas the Model A had a higher probability of driving away.

The Checker Model A was only made for two full years, 1939 and 1940. 1941 was a shortened model run due to WWII. Over the years the rumour grew up that Morris Markin melted down all the body tools and dies for the war effort. Automobile production ceased during the fight against Adolf Hitler and the Japanese. During this period, Checker participated in the fight by supplying the army with trailers to be used with that new invention of the war, the Jeep.

As the war ended, Checker was facing the challenge of designing and producing a new postwar car. During this period Checker utilized two innovative consultants, Herbert J Snow and Ray Dietrich. Snow was formerly the chief of engineering at Auburn-Cord-Duesenberg. While at A-C-D, Snow was the engineering leader who designed the front wheel drive system used on the classic Cord 810. Morris Markin hired Ray Dietrich as a consultant in May 1938, for the hefty sum of one hundred dollars a day. Like Snow, Dietrich was an experienced designer, having worked for Briggs, Le Baron and eventually Chrysler. Dietrich's rise at Chrysler was largely based to his redesign of the Chrysler Airflow, with his resulting Airstreams saving Chrysler from the sales failure of the Airflow.

Now, with two of the automotive industry's top engineers, Checker set out to introduce a replacement for the Model A. Called the Model B, the new, very unconventional Checker was to be very different from Checkers of the past, or for that matter any US produced car. Snow's proposal would be a rear engine/rear drive vehicle, much like the Volkswagen Microbus of the 1950s. In a memo in May 1945 Snow laid out his vision. He wrote, "The primary purpose of a vehicle of this kind is to carry passengers comfortably and economically. To do this, passengers must be placed in the most advantageous seating and riding position. The vehicle must be light if it is to operate economically. Keeping weight to a minimum means that the entire vehicle must be as compact as possible without any sacrifice in passenger space." The project progressed to the development of a mule. Designated the Model C, it utilized a sidevalve Continental 6 placed transversely in the rear of the cab, mated to a Warner three speed manual transmission. The overall length of the cab was 198.5 inches and the wheelbase was 100 inches. As was always the case with Checker being an “assembled car”, many components for the Model C were sourced from the “parts bin” of other makers and independent component producers. In the case of the test mule, the front and rear suspension, brakes and wheels were from Studebaker.

The test mule went through extensive testing, and the results were poor. Prior to his death, Snow recounted to automotive writer Karl Ludvigsen the facts of the project:

"The objections to this design were that a vehicle of this type with the engine mounted in the rear behind the rear axle cannot have good weight distribution on a short wheelbase. There was too much weight on the rear wheels for good roadability and performance. Furthermore we had passenger seats facing each other as in trains and this we considered would be very objectionable to the passengers who rode backwards in the front seat." Given its poor handling and questionable passenger comfort, the project was killed.

In the summer of 1945, Snow moved on to a new project, the Checker Model D. Like the Model C, it was unconventional. It would be a front wheel drive vehicle with a transverse engine mounted forward of the cab. Plans called for a significant number of variations to be produced, including sedans, limos, station wagons, coupes, convertibles and light trucks.

Two running prototypes, a five-passenger sedan and a seven-passenger taxicab, were developed. The prototypes were equipped with a transverse mounted Continental 6 cylinder engines mated to a 3-speed manual transmission. The prototypes rode on a 112-inch wheelbase within a total length of 189.5 inches, six inches shorter than the 1946 Ford sedan and a foot shorter than the Model C prototype. The Dietrich styling was quite attractive and current. Unlike the Model A, its front end styling was well integrated into the overall design of the car, bearing a very close resemblance to the 1941 Chrysler.

The two prototypes were tested for well over 100,000 miles. The taxicab was tested in real taxi service, accumulating over 35,000 miles and the sedan ran in tests totaling over 65,000 miles. According to Snow, quoted in Special Interest Auto Magazine in 1973, "The passengers commented on the excellent ride qualities and the drivers claimed it was easy to keep on the road, handled well in traffic and on the highway." Tested in the early winter, according to Snow: "In heavy blizzards under adverse road conditions, it performed exceptionally well, pulling out from curbs blocked with snow without difficulty." Although both vehicles tested well, in the end it appeared that the Model D would have a higher cost per unit to produce. Tests also indicated that maintenance cost for the more complex FWD Checker would be higher than Taxi operators would find acceptable. The Model D project was killed in 1946, which left Checker with a major problem. The company had not produced a car in close to five years and whatever Markin had done with the body tooling, there was none left from the Model A to continue production in the post war years. A new effort was initiated to quickly develop a modified version of the Model A; the resulting product would be the Model A2.

Checker rapidly developed a replacement for the Model A, combining the chassis and engine configuration of the original Model A with the Dietrich-designed body of the Model D. The resulting vehicle was called the Model A2. The body passenger compartment of the A2 is virtually identical to the Model D, the only difference being the length of the front clip, which was redesign to be configured for a front inline Continental 6-cylinder flathead engine and rear wheel drive configuration of the Model A. The Checker A2 dimensions were consistent with most large US produced automobiles at a total length of 205.5 inches and the wheelbase 124 inches.

The Model A2 was developed in less than one year and was introduced to the public on December 15, 1946, in Automotive Industries Magazine. Despite the limited time and fast-paced development time Herb Snow was still able to add his patented X-Frame to the new A2 thus continuing to set the bar for purpose built taxis. The A2 was a stylish car with pontoon fenders that flowed into the doors, a classic long hood and curvaceous passenger cabin. The body line behind the windshield was comparable with the styling on other classic cars of the period. Missing from the Model A were the driver roof vent, the glass roof and the landaulet opening roof.

The following year, in August 1947 Checker introduced another model, the A3. Called a pleasure car, this automobile was Checker's first official entry into the non-taxi market, a car that could be sold into the “Black Car” limo markets that were growing in most US cities. A deluxe version of the A2, the A3 sported a bench front seat and more chrome The Checker A3 was equipped with a rear trunk. This was the first time Checker had offered a trunk as standard equipment. The A2 did not have a trunk, mainly because many US cities still had laws on the books that prohibited taxis equipped with trunks. Many of these laws dated back to the prohibition era as rumrunners would transport illegal booze out of sight of the police in the trunks of taxicabs.

The company entered the consumer passenger car business in 1947 on a limited basis. By the late 1950s, CMC would further expand in consumer automobile market. Sales were phased in regionally across tTwo running prototypes, a five-passenger sedan and a seven-passenger taxicab were developed. The prototypes were equipped with a transverse mounted Continental 6 cylinder engines mated to a 3-speed manual transmission. The prototypes rode on a 112-inch wheelbase within a total length of 189.5 inches, six inches shorter than the 1946 Ford sedan and a foot shorter than the Model C prototype. The Dietrich styling was quite attractive and current. Unlike the Model A, its front end styling was well integrated into the overall design of the car, bearing a very close resemblance to the 1941 Chrysler. The end result was that the compact little cars were effective, efficient and stunning to boot.he US in 1959, starting in New York and New England. Nationally, introduction of the Checker Superba took place at the Chicago Auto Show on February 8, 1960.

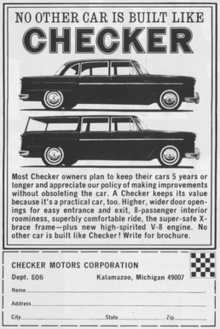

The dealer network continued to grow throughout the early 1960s, and throughout the decade Checker usually managed its target volume of 6000-7000 cars a year. In 1962, production topped 8000, although most of those were taxis. Four-door sedans and station wagons (Superba and Marathon models) also were advertised to individual customers in upscale publications. The ads emphasized the durability of the Checker and the attention to quality improvements. In 1962, almost 3,000 cars were sold to individuals—20% of production—but that percentage declined to 10% in the 1970s.

In addition to automobile production, Checker played a significant role as a third-party automotive supplier of OEM body stampings. In the late 1930s Checker produced truck bodies for Hudson in addition to manufacturing complete Ford truck cabs. Checker also produced truck bodies for the REO Motor Car Company.

During World War II Checker was one of many producers of the G518 Ben Hur trailer for the U.S. Army.

In 1964, the state of New York pursued Marking and Checker on antitrust charges, alleging that it controlled both the taxi service and manufacture of taxis, and thus favored itself in fulfilling orders. Rather than allow Checker drivers to begin buying different brands of cars, Markin began selling licenses in New York City.

The next year, the company switched from the standard Continental engine, offering either Chevrolet 230 cu in (3.8 l) overhead-valve I6s or 283 cu in (4.64 l) small block V8s.

1970s

By the 1970s the Checker cab design was several automotive generations old. As the decade started the Checker A11 design had been in production for close to twenty years. A11 design elements could be attributed to a 1950 clay design. Some chassis components had ancestral linkage to the 1939 Model A design. Clearly, it was time for Checker to consider developing a modern taxi that would allow Checker to produce cars into the next century. Several projects were executed in the 1970s in the attempt to develop a new Checker. In 1974, US Steel and prototype builder Autodynamics of Madison Heights, Michigan proposed a new Checker idea called “Galva” to CMC. The plan was to design a new Checker using newly developed manufacturing techniques to produce a vehicle with a reduced amount of tooling. Unfortunately, the project never got off the drawing board; Checker management was happy and profitable. Checker would continue to produce the A11 and various other specialty cars.

In March 1977, seven years after the death of Morris Markin, retired GM President Ed Cole and car dealer Victor Potamkin bought into Checker with the intent of re-energizing the company and developing a new, more modern Checker. With Cole as chairman and CEO of the company, the plan was to purchase partially completed Volkswagens from VW's new Westmoreland Assembly Plant in Pennsylvania. They were going to ship the Volkswagens to the Checker Motors factory in Kalamazoo, cut them in half, insert a section to lengthen the car, raise the roof and then sell the reconfigured vehicles as taxis. Less than 90 days after joining Checker, Cole died when his plane crashed near Kalamazoo in May 1977. In August 1977, the Checker-VW project was introduced in Road & Track magazine. The project was scrapped shortly after when it was determined that the Volkswagen was not suitable for taxi service.

1970's Model Data

| Model | Engine | Power | Transmission | Wheelbase | Length | Width | Ground clearance |

|---|---|---|---|---|---|---|---|

| Marathon | 250 CID I6 | 145 hp (108 kW) (1971); 110 hp (82 kW) (1978) | 3-speed automatic | 120 in (3,048 mm) | 204 in (5,182 mm) | 76 in (1,930 mm) | 7.5 in (191 mm) |

| A11E | 350 CID V8 | 245 hp (183 kW) (1971); 160 hp (120 kW) (1978) | 3-speed automatic | 129 in (3,277 mm) | 213 in (5,410 mm) | 76 in (1,930 mm) | 7.5 in (191 mm) |

1980s

By 1980 the US had gone through two energy crises, one in 1973 and one in 1979. Clearly it was time for Checker to consider developing a modern fuel efficient taxi that would allow the company to produce cars into the next century. The changes in the market were also making it harder and harder for Checker to find suitable off-the-shelf parts for their existing heavy vehicle, as General Motors (and Detroit overall) moved to producing lighter cars.

In the early 1980s, by way of a series of financial transactions, David Markin monetized CMC. Potamkin and Cole's widow were paid out and both exited the company. Markin had total control of CMC again and the funds available to produce a new Checker. Moving beyond the Rabbit/Golf project, Checker's next attempt at a new taxicab was initiated via a partnership with General Motors' Fisher Body division. In 1980, General Motors introduced the X-Car line which was a major departure from traditional GM design. It was a front-wheel-drive platform with a transverse engine, similar to the BMC Mini concept. The new Checker was to be front wheel drive, ironic as this concept was first tested by Checker in the mid-1940s with the Model D project.

The planned partnership would have Checker purchase Chevy Citation “bodies-in-white” and then Checker would assemble them for taxicab use. The project did produce one prototype Citation test mule, but the project was short-lived.

Reported in the July 16, 1981 “Coachman”, Fisher Body's divisional newsletter, GM could not assure Checker a continued supply of Citation bodies for a time period that met Checker's requirements. Remember that by 1981, Checker had used the same body for 25 years. GM's planned obsolescence policy would exit the Citation by 1985. Checker had planned on the Citation/Checker taxicab to be introduced in 1982. Clearly, Checker could not afford to spend significant dollars on a design that would be obsolete a mere three years later.

Checker's final attempts at introducing a new cab came in early 1981. CMC signed a contract with Autodynamics to develop a new model. The project was called Galva II, an extension of the project originally begun back in 1974. Autodynamics developed a design that would use the latest GM components developed under the GM X car program. If successful, Checker could retrofit GM components as developed on a Checker-built body and would not have to rely on the Citation body.

Fisher Body was also involved in the Galva project. Plans were made for Fisher to supply various body components: door locks, windows regulators, door hinges and door handles.

Consistent with the original Galva 1974 project, the new Checker would be based on limited tooling. Paul E. Newman of Autodynamics was quoted in Automobiles Quarterly; “We had a particular build concept for them (Checker). It involved a low cost tooling and break form panels”. Howard E. Klausmeier of Autodynamics was quoted in Automotive News: “The intent is to standardize componentry and simplify tooling and manufacturing as much as possible. The only curved glass will be the windshield. All other glass is flat. In addition, the components provide easy replacement for repair and maintenance using simplified attachment systems.”

In November 1981, Sab Hori describes more details of the new Checker for automotive writer John Melrose: "We’re going to try and do everything we can to make the cab easy to service ... We’ll have bolt-on fenders, possibly of plastic, and we’re considering bolt-on door panels made from either RIM (reinforced injection molding) or SMC (sheet molding compound) plastic because if a panel is damaged it would be easier to replace. The fenders will be friendly, flexible type, like those on Oldsmobile’s new sport Omega. We’re also thinking about plastic hoods, rear hatch doors and facias because the tooling costs are lower. As a low-volume producer, we have the advantage of not worrying about the slow cycle times needed in making plastic parts. And what we’re trying to do is go as far as possible with proven technology. Checker is so small that we can’t afford to be the leaders; we’ve got to be followers."

The new Checker would have a fully independent rear suspension. The design was based on a Firestone-developed system called the Marsh Mellow, a fabric reinforced rubber cylinder. A striking solution for Checker, the Marsh Mellow spring was known for reliability, corrosion resistance, low cost, and basic simplicity. Best of all from Checker's point of view, unlike a conventional rear leaf spring, if a Marsh Mellow spring fails, the cab would not have been taken off the road immediately. This feature would endear it to taxi fleets. Surely it could handle the pot -holed streets of New York City.

At the time of design, Head of CMC Engineering Sab Hori was quoted in Automotive News, “The New Generation of taxicab design will be a four door hatchback designed with identical bumpers, glass, lighting, engines, transmissions, and front/rear end styling. All four models will have surround-type frames, extended for longer vehicles”, indicating like CMC models of the past, several variation of wheelbase and configurations would be available.

David Markin was also quoted in Automotive News, stating that “[t]he new vehicle will be sold to both fleet operators and private individuals." Plans called for three different wheelbases: 109.0 in. for six passengers, 122.0 for eight passengers, and 128.0 for seating nine and a raised-roof paratransit vehicle with wheelchair capabilities.

Ultimately, the project was killed. Balancing the required investment in the new Checker compared to making similar investments in the third party production business, Checker opted out of automobile production.

In July 1982, the last Checker automobile left the Kalamazoo assembly plant. It was an A11 Taxi, painted in Chicago green and ivory livery. Checker was now out of the automobile manufacturing business. In 1989, Checker Motors and Checker Holding Company were involved in a reverse acquisition with International Controls Corporation (Great Dane Trailers), and the company later changed its name to CRA Holdings. The company was reorganized in 1995 into three wholly owned subsidiaries: Yellow Cab (owns and leases taxicabs in Chicago), Chicago Autoworks (taxicab repair and other services) and CMC Kalamazoo. Other subsidiaries include American Country Insurance Company (a provider of property and casualty insurance), Great Dane (the largest manufacturer of truck trailers, containers and chassis) and South Charleston Stamping & Manufacturing Company. The company was renamed Great Dane Limited Partnership, and was acquired by Chicago-based CC Industries.

Purchased in August 1989, South Charleston Stamping was sold by Checker to Mayflower Corp. in November 1996. South Charleston Stamping had been owned previously by Volkswagen and supported Volkswagen automobile production in Pennsylvania in the late 1970s.

Checker Motors operated as a subsidiary of CC Industries as an automotive subcontractor, primarily for General Motors, into the 21st century. Checker made body stamping for various GMC/Chevrolet truck lines and chassis components for Cadillac. David Markin, son of founder Morris Markin, continued to act as CMC Chief Executive Officer.

2000s

In 2008, due to the late-2000s recession and high gasoline prices, sales at GM and other automakers plummeted. As a major supplier to GM, Checker saw its sales drop significantly. The company had net sales of $61 million in 2008 and projected 2009 sales of only $34.5 million, a decline of 43%. During the summer of 2008, Checker employed about 340 workers.

While the United States economy was in full recession, Checker Motors CEO David Markin fell victim to the Ponzi scheme started and run by Bernie Madoff. David Markin's name appears five times on the official list of Madoff victims. One address on the list was 2016 North Pitcher Street, Kalamazoo, the same address as Checker Motors Corp.

On January 16, 2009, the 87-year-old Kalamazoo company filed in U.S. Bankruptcy Court in Grand Rapids, Michigan. Escalating raw material prices and dwindling sales for its customers' products were cited as the main reasons for the filing, but another reason was labor costs. It was reported that a deal with unionized labor could not be reached after a year of negotiations.

At the time of the bankruptcy, Checker's customer base included General Motors, Chrysler LLC, Ford Motor Company, Navistar International and GM Shanghai. Checker was the eighth-largest American auto supplier to go bankrupt in recent years. GM and Chrysler followed Checker's bankruptcy just several months later.

In February, Checker asked the U.S. Bankruptcy Court for Western Michigan to reject its contract with 125 union workers and eliminate health care and pension benefits for 176 union retirees. On February 27, 2009, the judge in Checker Motors Corp.'s bankruptcy case threw out the company's request to eliminate its labor agreement. Bankruptcy Judge James D. Gregg agreed with United Steelworkers Union Local 2-682 attorneys that the company had not treated all parties involved in the proceeding fairly when it awarded four top executives a total of $275,000 in retention bonuses prior to filing for bankruptcy.

In March 2009, a committee of unsecured creditors in the bankruptcy case asked Judge Gregg to consider whether negotiations among the union, United Steel Workers Local 2-682 and Checker Motors could resume and reach concessions or if a mediator should be brought in, according to court documents.

On April 4, 2009, Checker notified its more than 270 employees that CMC would close its business by the end of June.

In a bankruptcy court hearing Monday, April 6, 2009, CMC and labor union representatives said they intended to continue trying to negotiate a new union contract that would allow Checker Motors to survive.

In May Checker was given permission to enter into agreements with General Motors Corp. that were intended to help the bankrupt supplier stay afloat until it could negotiate the sale of itself to a new owner.

In late May, Checker announced that it found a potential buyer, the Narmco Group. On June 9, 2009, Judge Gregg approved the sale of Checker Motors Corp. to the subsidiaries of two Canadian automotive suppliers, Narmco Group LLC and Van-Rob Inc.

The Narmco Group, based in Windsor, Ontario, paid $650,000 for Checker's business of making stamped metal and welded assemblies for GM trucks and other vehicles. Van-Rob Inc., based in Aurora, Ontario, paid $950,000 for some of Checker's manufacturing equipment.

Christopher Grosman, an attorney representing Checker Motors, told Judge Gregg that the offers from Narmco and Van-Rob represented the "highest and best value" to Checker's creditors. Grosman said much of the company's machinery could not be sold because, in the wake of downsizing throughout the automotive industry, the market had been flooded with similar equipment.

The $1.6-million sale meant the end of the road for Checker. About 125 Checker workers in Kalamazoo made parts until June 30, then the business was transferred to Canada. In July 2009, General Motors Corp paid $1.5 million to Walker Tool and Dies for tools and dies that remained on site at Checker. Walker Tool had liens on the tools, so payment was required to move the tools to Canada. The tooling was transferred to Canada to make the Buick Lacrosse.

On January 14, 2010, the Checker Motor Company ceased to exist with the sale of its Kalamazoo headquarters. It was purchased for just under $3 million by a holding company, the Jones Group, which was to sell off the assets and clear the 72 acres. Checker president David Markin was quoted in the New York Times, "It's finished. Our family is very distressed about the closing of the company, but it became inevitable."

Commercial vehicles

Checker is best known for its taxicab, on which it built its business and reputation. In its early years Markin not only produced the vehicles but also ran Checker Cab, a taxi company that was in direct competition with John D. Hertz, owner of Yellow Cab.

During the 1930s Checker built trailers for Sears-Roebuck and truck cabs for Ford Motor Company. Checker also built four prototype Jeeps that were tested by the U.S. Army. They were developed in partnership with the American Bantam Company (a builder of Austin-based tiny autos) and featured four-wheel drive and four-wheel steering. During World War II Checker built tank retrieval trailers, tank recovery vehicles and semi-, petroleum and other types of trailers.

Checker designs changed infrequently; Markin held on to certain design features long after they were discontinued by major automobile manufacturers. For example, open front fenders were retained by Markin into the 1940s because it saved operators the expense of repairing minor dents. Taxicab models were designated by a letter series; significant modifications in models (new major systems, etc.) were designated by a number following the model letter.

Checker's commercial vehicles were usually given letter designations instead of model names (most notably variations of the Checker Model A). An exception to this rule was the Checker Aerobus, an extended version of its cars, built on a stretched wheelbase allowing for each row of seats to have its own doors. The Aerobus was often associated with airports and train stations, although vacation resorts also used Aerobuses for transporting guests.

Consumer vehicles

From 1922 to 1947, Checker's production vehicles were built almost exclusively for the commercial livery (taxi) business, although cars for personal use were available upon request. In 1947 the Checker Model A3 was introduced. The major difference between the A2 Taxicab was the inclusion of a full front bench seat and opening truck. Checker had limited success with the A3 pleasure car.

In 1956 Checker started to expand its distribution channel with the introduction of regional sales offices. When Checker introduced the Checker Model A8, it officially entered the retail sale market. Articles and reviews were generated in Consumer Reports and Motor Trend magazine.

Checker needed to enter the consumer vehicle market when taxi sales declined. New York City sales dropped significantly due to the new 1954 taxi commission regulations that expanded big three competition in the market. Checker needed to enter the retail market to fill plant capacity lost to the big 3.

Checker continued to expand its dealer network on a regional basis. The first new market after New York City was Boston and parts of New England. In February 1960 Checker introduced the Checker Superba nationally, its first model specifically built for the consumer market. Joining the Superba in 1962 was the Marathon, which took the place of the Superba Special. The Marathon consisted of standard- and long-wheelbase sedans, plus station wagons. Wagons came standard with a motorized fold-down rear seat, which — combined with different bodies — pushed the price $350 above the sedan. Limousines were also offered, as Checker sought to tap into yet another specialty market. The only engine was the Continental inline six, which had been used in dozens of cars (including Kaiser-Frazer) and trucks since the 1930s. Two versions were offered: a low-compression L-head unit with only 80 hp (60 kW) and an OHV unit with higher compression and 122 hp (91 kW). Three-on-the-tree manual shift was standard, and a Borg-Warner three-speed automatic with optional overdrive was an option. Civilian models were as utilitarian as their fleet counterparts, sporting a simple, flat dashboard with round gauges (this would remain unchanged up to the final Checkers in 1982), rubber mats instead of carpeting and hardboard ceilings. Floors were flat to allow easy entry and exit.

Checker's cars were lightly marketed, using campaigns that centered on their durability and unchanging style. Checker also promoted its vehicles as 200,000 mi (320,000 km) cars at a time when most United States automakers shied away from mileage promises.

The A12 Marathon and A11 Taxicab design was based on the 1956 Checker Model A8. The A8 was Checker's response to new New York City taxi laws that mandated taxis could not run on a chassis wheelbase longer than 120 in (3,000 mm). Checker cars and taxicabs used the same basic body and chassis design from 1956 until production ceased, as Morris Markin declared that there would be no major changes as long as there was a demand for the car. However, numerous alterations in the appearance of the cars were made throughout production, especially in the late 1960s and 1970s.

Starting in 1967, an energy-absorbing steering column was fitted to meet safety regulations, similar in appearance to AMC's column. Round side marker lights on each fender were added in 1968. Seat belts were fitted as mandated by the United States government, including shoulder belts on Checkers built after December 1967. The 1969 cars got high-rise headrests and 1970 models adopted the government-required steering column and shift lever lock. The 1974 Checkers eschewed the attractive, chrome-plated bumpers for girder-like, aluminum-painted units. The 1975 models featured the catalytic converter emissions device, which came with an "Unleaded Fuel Only" label for both fuel gauge and fuel filler. During the 1970s, Checkers adopted a standard Chevrolet steering column assembly, including steering wheel (without the "Chevrolet" badges), shift lever and ignition switch.

The 1978 and later models can be identified when Chevrolet switched to a "Delta Spoke" steering wheel design, duly used on Checkers. The rear fold-down jump seats were also removed, as they failed all safety tests. Parallel-action windshield wipers also appeared on the 1978 models. The car had very poor fuel economy, as the tall front end and engine compartment had been designed for a Continental 226-cubic-inch inline six, which required the large engine compartment.

Overall, Checker sales began shrinking in the 1970s, causing the company to reduce its production capacity. Limousines were dropped after 1970 and wagons followed in 1974. The standard- and long-wheelbase sedans remained until the end. This decline was due to a number of factors. First, the oil embargo of 1973-1974 (and later the 1979-1982 recession) caused the Big Three to lose consumer sales, and they attempted to make up for this by targeting the fleet market more aggressively.

Checker could not hope to compete on price, which due to inflation had risen to almost $5000 by the middle of the decade. This was Buick and Chrysler territory, and a large sum for a dated car with unimpressive build quality. Safety and emissions requirements added further costs. Meanwhile, the company refused several proposals for a replacement to its 20-year-old design. Automobile production ceased in 1982 after Checker's output dropped to less than 1,000 vehicles per year.

In 1964, Checker ceased using Continental engines. Continental had been losing money on each unit sold to Checker for several years and Checker was not interested in a price increase. Checker experimented with several engine options, including the Chrysler 318. Eventually it went to a Chevrolet straight six. That engine, along with an optional Chevrolet V-8, was used until the late 1970s. Engines and drivetrains matched the full-sized Chevrolet models. During the 1970s the Impala's Turbo-Hydramatic 400 transmission was fitted to all Checker sedans. Some of the last Checkers built were equipped with Oldsmobile 350 Diesel V8s.

When GM discontinued the straight six in its full-sized Chevrolet models for 1980, Checker purchased a small V6 that was also used in the big Chevrolets. However, the large and tall grill and hood made for poor aerodynamics, which contributed to the car's poor fuel economy. A number of the V6s were converted to use propane as fuel. Many of the body stamping dies were worn out after 20 years of use, and that required manual body adjustments by body-and-fender mechanics to make the parts fit. The fenders and doors were the most problematic, as taxis are involved in numerous minor accidents due to their heavy usage. With the Marathon outmoded and not selling in viable quantities, and with no resources to develop a new model, Checker decided to leave the auto manufacturing business. The last models were produced for the 1982 model year, and the final automobile rolled off the assembly line on July 12, 1982, after members of the Markin family decided to end production rather than meet labor demands. The last of the New York Checker taxicabs were retired in 1999, as a New York City taxicab ordinance was passed in 1996 in which livery vehicles must be replaced after six years of service.